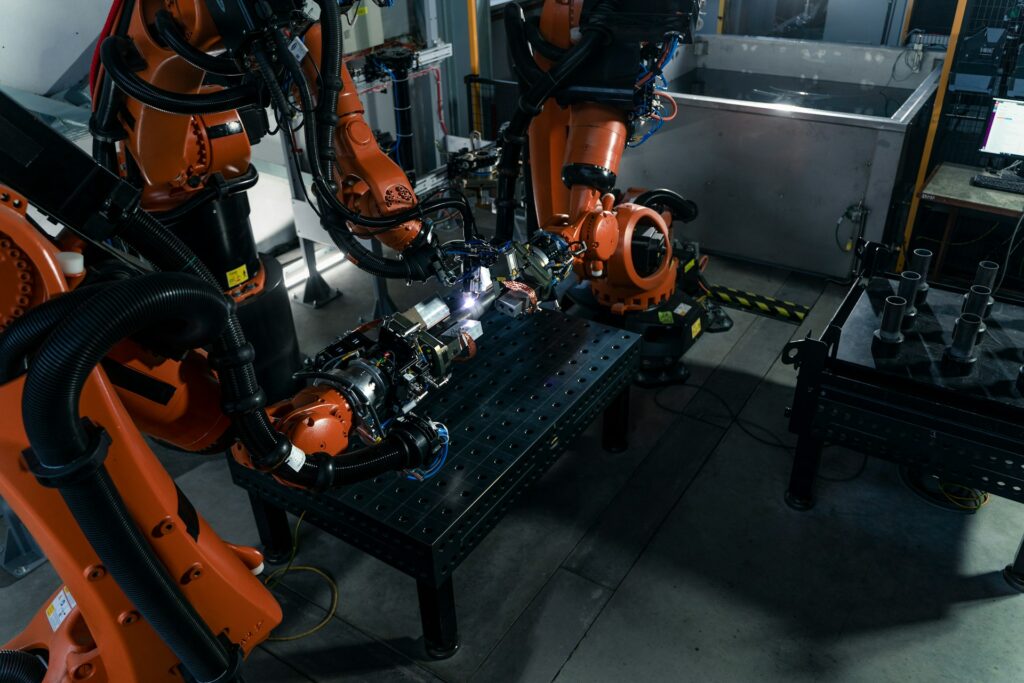

The rapid expansion of robotics and automation systems across diverse industries demands reliable and high-performance memory solutions to ensure seamless operation, accurate data processing, and longevity. Selecting the ideal industrial memory solution for these robotics applications can be a daunting task, given the plethora of available memory technologies and their varying capabilities.

That’s why we’re here to help you navigate the complex landscape of industrial memory solutions, offering valuable insights and practical tips to identify the perfect memory solution tailored to your specific robotics application. From ruggedised solid-state drives designed to withstand harsh industrial environments to high-speed memory modules optimised for real-time processing, we will provide a clear understanding of the options at your disposal.

How to Choose the Right Industrial Memory Solution

1. Assessing Application Requirements

Before selecting the ideal memory solution for your robotics application, it’s crucial to have a thorough understanding of your system’s specific requirements. Assessing these needs will ensure you choose a memory technology that not only meets but also enhances your application’s performance. Consider the following factors when reviewing your robotics application:

- Operating Environment: Evaluate whether your robotics system will be exposed to extreme temperatures, shock, vibration, or other challenging environmental conditions. Some memory technologies, like SLC NAND Flash, are better suited for harsh environments, ensuring reliable performance and longevity.

- Data Endurance: Determine the data endurance requirements of your robotics application, considering factors such as frequency of data reading/writing, storage capacity, and data retention needs. Industrial-grade memory solutions often provide higher endurance, facilitating reliable data storage and retrieval.

- Speed and Latency: Analyse the data processing speed and latency requirements of your robotics system. Some memory technologies, such as DDR SDRAM, deliver faster data transfer rates and lower latency times, which can be crucial for real-time robotics applications.

2. Understanding Memory Technologies

There are various memory technologies available in the market, each with specific characteristics that can influence their suitability for robotics applications. Here is an overview of some common memory types:

- SLC NAND Flash: Single-Level Cell (SLC) NAND Flash memory offers high endurance, fast read/write speeds, and excellent data retention. It is widely used in industrial applications, particularly those requiring long-term reliability and robust performance. However, it often has a higher price point compared to other NAND Flash types.

- MLC NAND Flash: Multi-Level Cell (MLC) NAND Flash memory stores multiple bits per cell, providing a more cost-effective option with higher storage capacities. However, it lacks endurance and performance compared to SLC NAND Flash. MLC technology might be suitable for robotics applications with moderate reliability and data endurance requirements.

- TLC NAND Flash: Triple-Level Cell (TLC) NAND Flash memory offers even higher storage capacities and lower costs than MLC NAND Flash, storing three bits per cell. However, it provides lower endurance and slower read/write speeds compared to SLC and MLC. TLC is generally less suitable for demanding robotics applications but can be used for cost-sensitive or less-critical applications.

3 A Closer Look at Memory Form Factors

Selecting the right memory form factor is another important consideration in choosing the ideal solution for robotics applications. Below are common form factors to consider:

- Solid-State Drives (SSDs): SSDs use NAND Flash memory, offering high-speed data transfer rates and robust endurance. They are an ideal choice for robotics applications that require dependable, long-lasting data storage. SSDs are available in various form factors, such as mSATA, SATA, and U.2, allowing for flexibility in system design and integration.

- SD and microSD Cards: Secure Digital (SD) and microSD cards utilise NAND Flash to provide removable and easily upgradable storage solutions. These memory options are suitable for robotics applications that require flexibility in storage capacity, quick data access, and portability.

- DRAM Modules: Dynamic Random Access Memory (DRAM) modules offer high-speed, volatile memory solutions for robotics applications that demand real-time data processing and retrieval. Common DRAM types include DDR, DDR2, DDR3, and DDR4. However, due to their volatile nature, DRAM modules are unsuitable for long-term data storage.

4. Importance of Customisation in Memory Solutions

Choosing the ideal memory solution for your robotics application is a vital decision, but don’t overlook the value of customisation to further enhance your system’s capabilities. Working with a reliable industrial memory supplier that offers personalised memory solutions can provide several advantages:

- Optimal Performance: Custom memory solutions can be tailored to your specific needs, ensuring your robotics system achieves the optimal performance required within its specific operating environment.

- Enhanced Reliability: Customisable memory solutions enable you to choose memory technologies and form factors that meet rigorous standards, ensuring enhanced reliability and long-term operation.

- Streamlined Integration: Custom memory options enable seamless integration and a streamlined design process, addressing unique challenges and complexities that may arise in robotics applications.

5. Selecting a Trusted Memory Provider

Choosing a reliable industrial memory provider is as crucial as selecting the ideal memory solution. Partnering with an experienced and reputable memory supplier, such as Nexus, offers the following benefits:

- Technical Expertise: A trusted provider possesses in-depth knowledge of memory technologies, crucial for guiding you in selecting the most suitable solution for your robotics application.

- Quality Assurance: Reputable memory suppliers adhere to strict quality control measures, ensuring that industrial memory solutions meet stringent reliability, endurance, and performance requirements.

- Customer Support: A reliable memory provider offers comprehensive customer support, helping you navigate technical challenges and consult on custom memory solutions that best fit your robotics application needs.

Empowering Robotics Applications with Nexus Solutions

The ideal industrial memory solution for your robotics application hinges on various factors, including application requirements, memory technologies, form factors, and customisation opportunities. By comprehensively evaluating these aspects and partnering with a trusted memory provider like Nexus, you can ensure your robotics system achieves optimal performance, reliability, and longevity.

Experience the benefits of tailored memory products designed to suit your unique robotics and automation requirements. Browse Nexus’s extensive range of industrial-grade memory solutions and discover the ideal fit for your application.

Get in touch with the expert team at Nexus today to discuss your memory requirements, explore custom memory options, and empower your robotics system with the best-in-class memory solutions for seamless, reliable operation.