IoT-enabled devices used in industrial applications are vulnerable to many forms of cyberattack. Michael Barrett, managing director of Nexus Industrial Memory, outlines some ways in which devices might be attacked and suggests how they can be made more secure.

IoT-enabled devices used in industrial applications are vulnerable to many forms of cyberattack. Michael Barrett, managing director of Nexus Industrial Memory, outlines some ways in which devices might be attacked and suggests how they can be made more secure.

Security is a growing concern for the IoT and its industrial counterpart (the IIoT) so I won’t recount any numbers, stats or cyberattack stories here. There are plenty online and they’re making the news all the time. What is worthy of mention though is that those attacking IIoT have different objectives to those attacking IoT.

For instance, IIoT data theft is more likely to be about acquiring industrially sensitive information, and ransomware attacks will be out to disable equipment and halt processes. Other attacks, many of which are state-sponsored, aim to cause damage by compromising safety-critical systems.

If a device is connected to the internet it is exposed to cyberattacks, and if it still uses the default username and password with which it left the factory it may as well have no security at all. For example, Mirai, a self-propagating botnet (a.k.a. zombie), attacks poorly protected systems using telnet to find devices that are still using their default username and password.

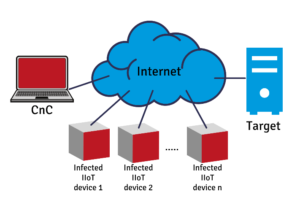

If these devices are used in multiple locations around the world – to report performance and diagnostic data back to a single server, for example – they can be instructed (from a command-and-control, CnC, centre) to perform a distributed denial of service (DDoS) attack. See figure 1.

In many cases though it is not necessary to rely on the user failing to change a default password. There’s another way in; through data the device is expecting to receive. For instance, a common form of attack on IoT-enabled devices, and for which the programs are written in a low-level language like C, is through a forced memory buffer overflow.

The spearhead of the attack is to write data to memory reserved for run-time activities that is larger than that which the device expects to receive. The excess data overflows into other memory space and overwrites machine code that governs the system’s behaviour.

If the overflow data is something like a new return address, a different part of the program will execute next. This might be a legitimate function, such as the restoration of factory settings (including default passwords). Or the hacker can simply set a new password. Either way, the hacker has access to the system. However, the legitimate user might wonder why they no longer have access.

A more severe memory buffer overflow attack sees the introduction of shellcode to give the device new behaviour. This might be to reveal the password set by the legitimate user of the system. Or it could be to reveal the password the device uses to get on to the network and communicate with other devices. The legitimate user may never know the device has been compromised.

As for how the hacker knows where to write the overflow data and what it should be, if the device is an off-the-shelf product, it can be reverse engineered to establish its memory map.

One way of protecting against memory buffer overflow attacks is not to program in a low-level language. Instead, use C# or Java, for example. Also, if there’s room for an operating system then it is likely to provide a form of memory management. If not, dedicated memory management unit (MMU) chips can be used. Either way, certain areas of the device’s memory need to be protected (declared as Read Only, for example) during runtime.

An IIoT device can also be attacked through its application program interface (API). Many devices use a representational state transfer (REST) based API called RESTful. Such APIs are popular because they do not require much bandwidth, can be crafted in Python or JavaScript, and they use HTTP to communicate with the cloud. This means data can be created, updated, read or deleted.

The use of any REST-based API presents certain cyber challenges. These can be addressed through better authentication for access control, blocking certain payloads (size and/or type that aren’t expected) and access from unknown IP addresses and domains. If the IIoT-based device is just one of few that is part of a well-conceived IT and operating technology (OT) system none of these solutions should prove too difficult to implement.

Secure by design

Traditionally, security considerations have always come late during product development, sometimes as late as prototyping. That needs to change. Security needs to be considered when specifying a device’s requirements. Its intended length of service in the field and importance of what it does and the data it provides/receives will govern the kind of measures that need to be taken.

Let’s assume high security is required and consider, for a moment, end-to-end communications. An important element is the device’s identity. How trustworthy is it? Is static data encrypted on the device? Should/can data in transit be encrypted to thwart ‘man-in-the-middle’ interceptions?

Thankfully, the OEMs of microcontrollers are producing some great ICs that are very much geared for high security IoT life. Take Microchip Technology’s CryptoAuthentication family of devices, for example. They can work alongside the microcontroller or microprocessor within an IoT-enabled devices. IC features include a unique and non-changeable 72-bit serial number (set by Microchip), a 512bit one-time programmable (OTP) zone, a random number generator and a SHA-256 hash algorithm for data encryption. They also include APIs for storing, retrieving and manipulating X.509 certificates for Transport Layer Security (TLS) integration.

In the example I gave earlier – a server communicating with multiple IIoT-enabled devices – the end-to-end communications link can be made far more secure by virtue of unique IDs in the field and transferred data being encrypted.

IIoT in Automation

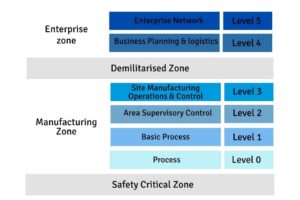

The IIoT is very much part of Industry 4.0 and M2M. It has brought great benefits. However, IIoT is challenging the Purdue Model (see figure 2), which reflects the hierarchy of IT and OT systems elements, and comprises six layers.

- Level 5 = corporate network systems.

- Level 4 = IT systems for business logistics (includes databases and servers)

- Level 3 = systems for site-wide monitoring and control

- Level 2 = control systems such as HMIs and SCADA software

- Level 1 = basic control devices such a programmable logic controllers

- Level 0 = sensors, actuators, motors and pumps etc.

The purpose of the Purdue architecture is to assure safe control, noting that safety and security go hand-in-hand. Within the enterprise zone it has historically been only the enterprise network that has had access to the internet and the outside world. Malware hitting IT equipment at levels 5 or 4 should not be able to affect anything at level 3 or lower because of the firewalled demilitarised zone.

Today, many OT devices in the manufacturing zone are now IoT-enabled. Smart sensors and controllers, along with edge-processing systems, are connected to the internet. Data no longer flows between the Purdue Model levels.

There are mixed views in the industry whether the Purdue Model needs to be replaced or enhanced in light of the increased use of IIoT within the manufacturing zone. As stressed earlier, a risk analysis must be performed on any IIoT device relative to its level in the Purdue model and whether it is playing a role in monitoring, controlling or both.

Figure 1 – The attacker uses the CnC to instruct infected devices to inundate the IP address of a target system with requests to communicate, thus denying legitimate users access to the system.

Figure 2 – Since the 1990s, the Purdue Model has been standard for enterprise and industrial control system networks.

Figure 2 – Since the 1990s, the Purdue Model has been standard for enterprise and industrial control system networks.

This article appeared in the November 2021 issue of Automation magazine. It appeared in print, is online and is reproduced on our site with the editor’s kind permission here.